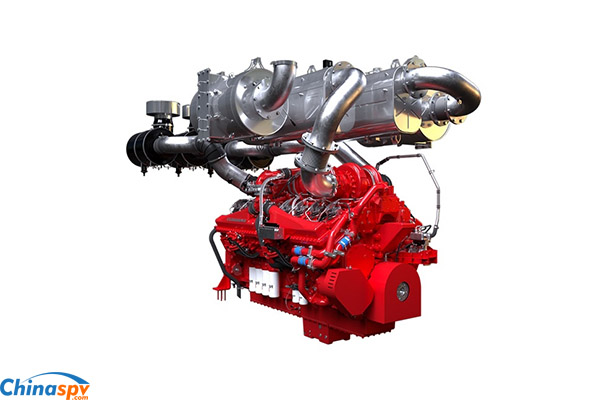

From cost saving to reduction in environmental impact, dual fuel has a number of key benefits when utilized in oil and gas applications. The reduction in diesel consumption when running in a dual fuel operation, helps to give customers both savings in operation expenses as well as reduce the impact transportation and refining has on the environment. The dual fuel application also provides customers with the reliability of a traditional diesel engine, by offering the same power density and transient response as its diesel-only counterparts, while operating at an optimized substitution rate tailored to the oil and gas market.

Cummins’ dual fuel solution will feature integrated controls, permitting a seamless transition from diesel fuel to dual fuel operation. When the engine is operating in dual fuel mode, natural gas is introduced into the intake system, reducing diesel consumption while maintaining power density, torque, and transient response matched to the base diesel engine.

The Cummins dual fuel solution is achieved via a kit of dual fuel components integrated with the QSK50 Tier 4 final engine. The kit will be available for first fit solutions and as a retrofittable solution to existing QSK50 Tier 4 final engines. Either solution will provide the customer flexibility in their operations, and deliver an improved total cost of ownership that customers have come to expect with a Cummins solution.